Ecosystems

Ecosystems

High Performance Computing Solutions

A diverse range of modular components to kickstart any high performance computing (HPC) operation.

Tailor-made to optimize your infrastructure ...

Energy Storage & Battery Solution

A circular approach to energy - Storgi Energy Ecosystem redefines production, usage, and disposal, focusing on sustainability and efficiency.

Advanced Scalable Mining Solutions

M-Line mining containers meticulously crafted for the dynamic world of data centers and crypto mining operations. Emphasizing scalability, preci...

Looking for something else?

Let's talkLooking for something else?

Let's talkDiscover our ecosystems

High Performance Computing Solutions

A diverse range of modular components to kickstart any high performance computing (HPC) operation.

Tailor-made to optimize your infrastructure ...

Advanced Scalable Mining Solutions

M-Line mining containers meticulously crafted for the dynamic world of data centers and crypto mining operations. Emphasizing scalability, preci...

Energy Storage & Battery Solution

A circular approach to energy - Storgi Energy Ecosystem redefines production, usage, and disposal, focusing on sustainability and efficiency.

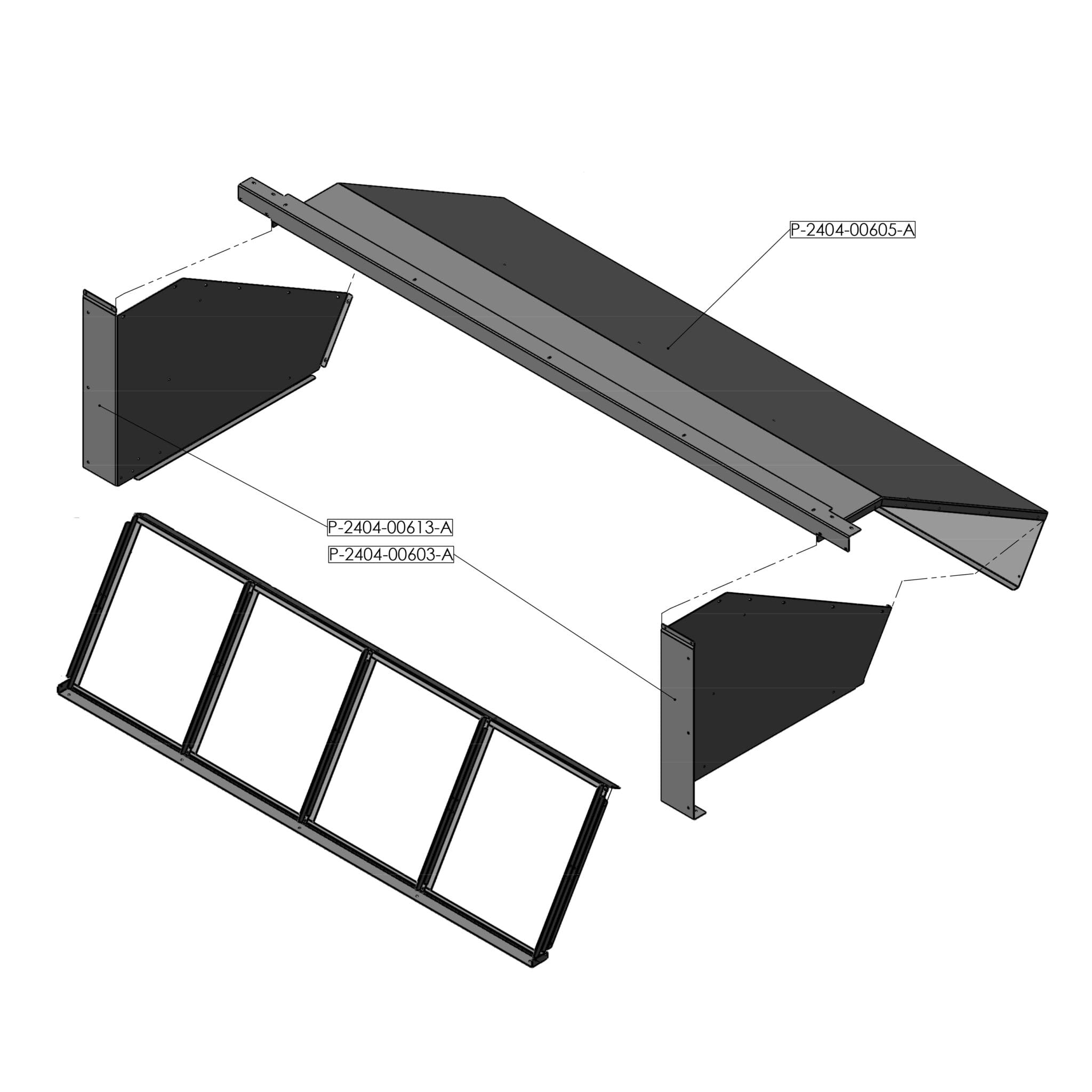

Featured KONNECT HPC modules

Discover KONNECT HPC ecosystemFeatured M-Line Mining modules

Discover M-Line Mining ecosystemFeatured STORGI Energy modules

Discover STORGI Energy ecosystemLooking for something else?

Let's talk